Overview

Silicon carbide vortex spray nozzle, AKA swirl nozzle, tangential nozzle, is adopted for exhaust gas washing, gas cooling, washing and bleaching process, fire prevention and extinguishing, flue gas desulfurization system and dust removal system. With high strength, high hardness, corrosion resistance, wear resistance, high-temperature resistance and other excellent performance, it is the key component of thermal power plants, large boilers, complete sets of desulfurization and dust removal devices.

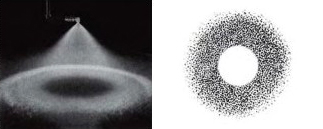

It mainly includes hollow and solid cones(with unidirectional and bidirectional eddy current respectively). The swirl nozzle has the advantages of simple structure, uniform atomization and convenient operation, and has the characteristics of misalignment between the center of the ejector pump and the inlet axis. It sprays in a conical hollow circular ring. And the small-sized atomizing particle is free of clogging. The injection angles are 90° and 120°.

Oustek’s Silicon carbide vortex nozzle adopts isostatic pressing, net size sintering and mechanical finishing technique, it produces a vortex nozzle with density up to 3.1kg/m³. Adopts silicon carbide for high-quality refractories with purity up to 98.5%, so the maximum working temperature reaches up to 1380 ℃ (2500 ℉).

Application

- Desulfurization and denitration of power plants and coal-fired Enterprises

- Purification, cooling and defoaming of gas

- Evaporation, cooling and dust control

- environmental protection wet dust removal spray

- Pre-treatment requires non-blocking spray.

- Gas cooling

- Waste gas washing

- Fire protection and Application

- Dust-proof application in steel and petrochemical industry

Features

- With porosity lower than 0.1% and atomization more uniform, it smooths the internal flow channel.

- High strength, high hardness, wear resistance, density reaches 3.1kg / m3

- High thermal conductivity, low thermal expansion, high thermal shock resistance, high temperature creep resistance

- Chemically stable, resistant to corrosion, especially hydrofluoric acid

- High-temperature resistance, the maximum working temperature can reach 1380 ° C (2500 ° F)

- Long service life and reduce overall investment costs

Hollow Cone Spray

Full Cone Spray

ADVANTAGE & GUARANTE

Isostatic Pressing

With self-own isostatic pressing equipment, all products use isostatic pressing technology to make the green body uniformly stressed, the density distribution is uniform, and the product performance is greatly improved. There are incomparable advantages when molding complex shapes, elongated products, large-sized products, and precision-sized products.

Production & Management

Our factory has 10 complete production lines and 30 employees, including 10 technical personnel, 4 engineers, and 5 management personnel. Monthly production reaches 10 thousand (vortex nozzle). We passed the ISO 9001: 2015 quality system certification, making the production process more standardized, improving the management level and production x…

Test Report

The silicon carbide products we produce comply with Chinese national standard GB / T 21944 2009. After testing by Sinochem, we provide reliable test reports for product quality and provide data basis for optimization and research and development of production formulas.

Shipping & Packing

We guarantee intact during transportation, loading and unloading, and have measures to reduce vibration and impact, so as to ensure the integrity of the product during transportation. And promise a 15-month product warranty.